in the present entire world of ever more impressive and compact electronics, efficient thermal management is no longer a luxurious – it's a requirement. Overheating may lead to diminished overall performance, program instability, and even catastrophic failure. that is where by custom warmth sinks are available. as opposed to off-the-shelf solutions, custom styles are tailored to the precise requirements of your respective application, making sure ideal heat dissipation and reputable operation. This guideline will investigate the very important purpose of custom warmth sinks, specifically Extruded Profiles Heatsink, in numerous industries and provide insights into building and balancing Value with overall performance.

Table of contents:

vital Industries That reap the benefits of customized warmth Sink remedies

how you can structure a personalized Heat Sink for Optimal Thermal administration

Cost vs. general performance: Balancing customized warmth Sink Specifications

essential Industries That reap the benefits of tailor made warmth Sink options

Numerous industries trust in personalized warmth sinks to keep up the effectiveness and longevity in their Digital components. The telecommunications sector, with its dense networking gear, Rewards drastically from tailored thermal alternatives that avoid overheating and make certain uninterrupted provider. in the same way, the facility electronics marketplace, working with superior-voltage and substantial-latest apps, necessitates robust warmth sinks to control the intense warmth produced by electricity transistors and rectifiers. Furthermore, the aerospace and defense industries, where by reliability less than Serious circumstances is paramount, count on custom layouts to face up to harsh environments and sustain essential process performance. Even in medical devices, exactly where precision and safety are crucial, custom warmth sinks Perform a vital purpose in preventing overheating and making sure exact diagnoses and therapies.

tips on how to design and style a Custom warmth Sink for optimum Thermal administration

Designing a successful tailor made heat sink includes careful thought of a number of variables. to start with, being familiar with the heat source and its thermal attributes is crucial. This features figuring out the ability dissipation, temperature limits, and mounting necessities. subsequent, picking out the proper substance is crucial. Aluminum is a well-liked choice because of its outstanding thermal conductivity, light-weight, and cost-success, earning Extruded Profiles Heatsink a common Answer. Copper provides superior thermal general performance but is heavier and more expensive. The geometry of the heat sink is also important. Fin density, fin peak, and foundation thickness all effects the heat sink's power to dissipate heat. Computational Fluid Dynamics (CFD) simulations can be utilized to improve the design and forecast thermal functionality just before Bodily prototypes are designed. thinking about airflow and ventilation in the enclosure is also important, as right airflow enhances the warmth sink's usefulness.

Expense vs. general performance: Balancing Custom warmth Sink specs

although maximizing thermal functionality can be a Principal intention, Price tag can also be a substantial thought when building customized heat sinks. larger-general performance components like copper will improve the All round cost compared to aluminum. likewise, advanced geometries that have to have intricate machining or specialized production procedures may even generate up fees. Choosing the suitable production course of action, such as extrusion for Extruded Profiles Heatsink, can considerably influence Charge-usefulness. it is vital to diligently Assess the thermal necessities of your respective application and determine spots where performance could be balanced with cost cost savings. as an example, optimizing fin density or deciding upon a far more Expense-effective alloy can generally provide a excellent stability in between thermal functionality and funds. Sourcing your personalized heat sinks from dependable manufacturers who give design and style aid and price engineering can further more assist in accomplishing the optimum Price-overall performance ratio. Renxin Precision, one example is, presents A variety of tailor made heat sink remedies and can offer qualified steerage on optimizing your style for equally general performance and cost.

In summary, customized heat sinks are critical elements for guaranteeing the dependability and overall performance of Digital devices in an array of industries. By being familiar with The main element style and design criteria Extruded Profiles Heatsink and thoroughly balancing Price with performance, you could produce a custom made thermal Alternative that fulfills the specific desires of your respective software. Do not be reluctant to check out the key benefits of Extruded Profiles Heatsink and seek advice from with skilled makers like Renxin Precision to find an ideal Option in your thermal management worries. begin optimizing your thermal general performance today!

Ariana Richards Then & Now!

Ariana Richards Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Robbie Rist Then & Now!

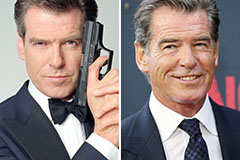

Robbie Rist Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!